CoroDrill® DE10

The exchangeable-tip drill for high-volume hole making

Outperformed competitor in stainless steel

Productivity

Tool life

| Country: | Italy |

| Component: | Plate |

| Material: | M1.0.Z.AQ, AISI316L, austenitic stainless steel |

| Operation: | 52 mm, one part through hole and one part blind hole |

| Machine: | Doosan NHP6300 |

| Coolant: | Emulsion 8%, 70 bar (1015 PSI) |

Challenge: Due to the cost of the component, reliability and repeatability are the most important factors.

Result: CoroDrill® DE10 had very good sound level and chip form was like the competitor. The hole surface quality was good and the hole diameter was in line with expectations. Even longer tool life is expected with grade GC2334.

| Competitor | CoroDrill® DE10 | |

| Tool | - | DE10-D1600-160L20-5 |

| Drill tip | - | DE10-1650-160-M5 4334 |

| vc, m/min | 40 | 55 |

| n, rpm | 772 | 1060 |

| fn, mm | 0.14 | 0.16 |

| vf, mm/min | 108 | 170 |

| Tool life, holes | 126 | 180 |

| Tool life, m | 6.6 | 9.3 |

| Tool life, minutes | 61 | 55 |

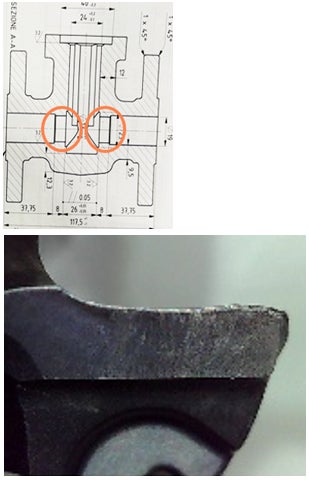

Unmatched performance in difficult application

Productivity

| Country: | Italy |

| Component: | Valve |

| Material: | M3.2.Z.AQ, machined super duplex stainless steel |

| Operation: | Through hole, 2×10 mm deep, irregular exit |

| Machine: | Doosan GT3100 |

| Coolant: | Emulsion 10% |

Challenge: The customer has problems with long chips wrapping around the drill. Uses low entering feed in steps and has poor productivity and tool life.

Result: CoroDrill® DE10 has improved productivity and chip breakage, with no chips wrapped around the drill. When tested with the same cutting parameters, CoroDrill® DE10 doubled the tool life. Even longer tool life is expected with grade GC2334.

Competitor, 10 pcs

CoroDrill® DE10, 30 pcs

| Competitor | CoroDrill® DE10 | |

| Tool | - | DE10-D1700-170L20-5 |

| Drill tip | - | DE10-1710-170-M5 4334 |

| vc, m/min | 43 | 50 |

| n, rpm | 800 | 930 |

| fn, mm | 0.08–0.06 | 0.15–0.1 |

| vf, mm/min | 64-48 | 140–93 |

| Tool life, holes | 60 | 60 |

| Tool life, m | 0.3 | 0.3 |

| Tool life, minutes | 10.2 | 5.4 |

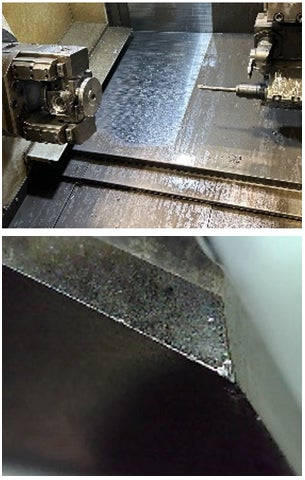

Excellent performance in lathe application

Productivity

Tool life

| Country: | India |

| Component: | Pin |

| Material: | P2.1.Z.AN, 17Cr3, alloyed steel |

| Operation: | 84 mm drilling in lathe |

| Machine: | RoboTurn FAR |

| Coolant: | Emulsion |

Challenge: Chip breaking and chip control are very important. Chips should not obstruct the working of the conveyor and gantry. Competitor chips are not consistent, and snarls of varied lengths are reported.

Result: CoroDrill® DE10 provided increased productivity and tool life, with good corner security and chips.

| Competitor | CoroDrill® DE10 | |

| Tool | - | DE10-D1700-170L20-5 |

| Drill tip | - | DE10-1750-170-M5 4334 |

| vc, m/min | 71 | 97 |

| n, rpm | 1300 | 1765 |

| fn, mm | 0.2 | 0.22 |

| vf, mm/min | 260 | 388 |

| Tool life, holes | 1200 | 1650 |

| Tool life, m | 101 | 138 |

| Tool life, minutes | 388 | 357 |

Join us. Stay updated.

Sign up for our newsletter today