CoroDrill® DS20

4–7×DC insert drill that offers reliability, predictability and outstanding penetration rates.

Strong and fatigue-resistant drill body

Each drill body size is individually optimized and has a never-before-seen stiffness to ensure high process security, repeatability, consistent quality and good run-out accuracy. Twisted coolant holes for maintained drill body rigidity and variable chip flutes with optimized shapes for safe chip evacuation.

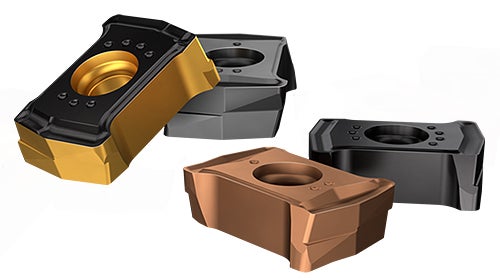

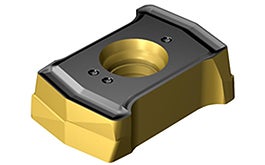

Optimized insert design

The robust insert seats have three support contact surfaces for less insert movements. The inserts are strong and have a bulk strength that provides extra toughness resulting in unmatched insert tool life. The ground peripheral insert allows for closer hole tolerance, predictability and consistent performance.

For holes up to 7×DC

This 7×DC insert drill with innovative drill body and insert designs makes it possible for cost-effective and reliable drilling of deep holes with less demanding hole tolerances. No pilot drilling needed which saves both time and money.

Application area

|  |  |

| Conventional drilling | Inclined exits | Inclined surfaces |

|  | |

| Cross holes | Convex/concave surfaces |

- Diameter range and depth capacity:

15–45 mm (0.625–1.75 inch), 4–7×DC

46–65 mm (1.875–2.50 inch), 4–5×DC - Hole tolerance:

4–5×DC: H12–H13

6–7×DC: -0.1/+0.5 mm (-0.004/+0.020 inch) - Capable of both non-rotating and rotating set-ups

- Can be used for drilling with radial offset, boring and deburring

Product range

Cylindrical shank with flat (ISO 9766)

4–7×DC: Diameter 15–45 mm (0.625–1.75 inch)

4–5×DC: Diameter 46–65 mm (1.875–2.50 inch)

MDI shank

4, 7×DC: Diameter 15–45 mm (0.625–1.75 inch)

4×DC: Diameter 46–59 mm (1.875–2.25 inch)

MDI adaptor

Coromant Capto®: C3, C4, C5, C6 and C8

HSK-T: 63 and 100

Tailor Made® drills

Do not find what you need in our extensive standard programme? Further optimization to your exact specification is possible using Tailor Made®.

Central insert

Grade: GC1344, GC1144, H13A

Geometries: -L5, -M7

Peripheral insert

Grade: GC4334, GC2044, GC4344

GC4324, H13A

Geometries: -S5W, -L5W , -L6W,

-M7W, -H5W

CoroDrill® DS20 catalogue

Download the catalogue for more information about CoroDrill® DS20, a complete standard assortment list and cutting data recommendations.

Hole tolerance

Drill depth 4–5×DC

| Drill diameter, mm (inch) | Hole tolerance, mm (inch) |

| 15.00–18.00 (0.591–0.709) | 0/+0.27 (0/+0.011) |

| 18.01–30.00 (0.709–1.18) | 0/+0.33 (0/+0.013) |

| 30.01–65.00 (1.18–2.56) | 0/+0.39 (0/+0.015) |

Drill depth 6–7×DC

| Drill diameter, mm (inch) | Hole tolerance, mm (inch) |

| 15.00–18.00 (0.591–0.709) | -0.1/+0.5 (-0.004/+0.020) |

| 18.01–30.00 (0.709–1.18) | -0.1/+0.5 (-0.004/+0.020) |

| 30.01–65.00 (1.18–2.56) | -0.1/+0.5 (-0.004/+0.020) |

Dimension control

Use an eccentric sleeve in order to get close hole tolerances or to change the tool dimension. Note! Not recommended for 6–7 × DC.

MDI (Modular Drilling Interface)

MDI is a stable and high precision drilling interface. The modular coupling between drill and adaptor allows you to use one size for several drill diameters leading to less tool inventory and lower costs.

Four locating pins allow for high torque transmission and provide an exact cutting edge position and quick and easy set-up.

With two different diameters on shank and adaptor, double centring with high fitting accuracy is possible. In combination with flange and surface contact between drill body and nut, increased stability, good run-out precision and optimal repeatability can be achieved.

Machine side interface

Coromant Capto®

| Size | MDI size |

| C3 | 20 |

| C4 | 20, 25, 32 |

| C5 | 20, 25, 32, 40 |

| C6 | 20, 25, 32, 40, 50 |

| C8 | 25, 32, 40, 50 |

HSK-T

| Size | MDI Size |

| 63 | 20, 25, 32, 40 |

| 100 | 25, 32, 40, 50 |

| MDI size | Drill dimension, mm (inch) | Keys |

| 20 | 15.00–17.43 (0.591–0.686) | 5680 103-05 |

| 25 | 17.44–25.99 (0.687–1.023) | 5680 103-06 |

| 32 | 26.00–31.99 (1.024–1.259) | 5680 103-07 |

| 40 | 32.00–43.99 (1.260–1.732) | 5680 103-08 |

| 50 | 44.00–59.00 (1.733–2.323) | 5680 103-09 |

Torque wrench recommendation: ER-TK-02M

(key interface 16)

Highlights

Opening up for new possibilities

A customer in Mexico found a new way of machining their components using the CoroDrill® DS20. Watch the film and find out how!

Reliable and predictable drilling

4–7×DC insert drill with innovative drill body and insert designs allow for reliable and predictable drilling.

Drilling inserts and grades

Find the right drilling insert grade for your workpiece material, hole diameter, hole depth and required hole quality here.

Join us. Stay updated.

Sign up for our newsletter today