CoroDrill® 865

CoroDrill® 865 geometry offers increased productivity and stable drilling of deep holes up to 30 times the cutting diameter. Optimized for cast iron, steel and aluminium, CoroDrill 865 offers high penetration rates, repeatability and process security.

Instruction for CoroDrill 865 Crankshaft Drill

Tool run out

Machine setup and holding is crucial for oil hole drilling, with a maximum recommended tool run-out of 30 microns (0.03 mm, 0,00118 inch).

Coolant

CoroDrill 865 comes with an MQL (minimum quantity lubrication) compatible shank as standard. For optimised performance, it is vital the MQL flow and pressure is well controlled.

Step by step guide

Produce precise inclined oil holes by following these simple steps. Always start with the dedicated pilot drill, and follow the coolant- and cutting data recommendations in this guide.

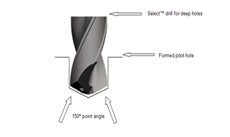

Pilot hole drill

Use the dedicated pilot hole drill with CoroDrill 865 to ensure precise and reliable cutting action and hole position. It has a manufacturing body tolerance of p7 and a 150 degree point angle. The CoroDrill 865 has an m7 manufacturing tolerance and 135-degree point angle.

Highlights

Welcome to Motor City

The engine is the heart of a car, and in a Volvo all that power is created in Skövde, widely known as Sweden’s motor city. The latest addition on the production line at Volvo Cars is the new-generation four-cylinder Drive-E powertrain engine.

Crankshaft manufacturing

The asymmetrical, long and relatively slender crankshaft is the heart of any combustion engine, from mopeds to heavy trucks. It is also one of the most challenging components to machine.

Sandvik Coromant wins Volvo Cars Award of Excellence

The Volvo Cars Award of Excellence was created in 1998 to acknowledge the outstanding contribution made by suppliers that have gone the extra mile and contributed to the success of this world famous automotive manufacturer.

Join us. Stay updated.

Sign up for our newsletter today