Milling inserts and grades for titanium and HRSA

Our milling inserts and grades for HRSA and titanium make use of the latest technology and developments in cutting tool materials. Find the right insert grade to meet the tough demands of HRSA and titanium milling here.

S30T

This is a PVD-coated carbide grade optimized for titanium milling; excellent for finishing to light roughing. This thin-coated grade enables very sharp cutting edges that resist fatigue and micro-chipping, for cutting edges that are preserved for longer times in cut at higher cutting speeds.Benefits and features

Titanium milling grade S30T

Learn more about state-of-the-art tools for aerospace landing gear beams.

Titanium milling with CoroMill® 690

CoroMill® 690 is designed with end coolant, providing the best chip evacuation when face and shoulder milling, whether cavity or pocket milling.

Zertivo™ – process control at a higher level

Zertivo™ is a unique production technology bringing longer tool life and enhanced security to PVD grades.

Get started with HRSA and titanium milling

Both HRSA and titanium have poor machinability, especially when aged, which places particular demands on the cutting tools.

Find your grade

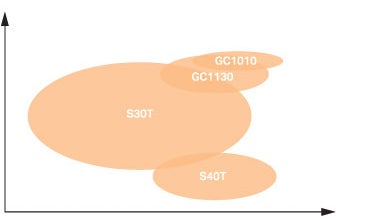

Our HRSA and titanium grade chain includes PVD- and CVD-coated carbide grades along with uncoated carbide grades for various machining conditions. Use the information below to find the right grade for your production.

| Stable conditions |  | |

| Unstable conditions | ||

Low heat (Small cutters | High heat (Large cutters |

S30T

Medium-hard PVD-coated grade with thin coating, for finishing to light roughing applications in rather stable conditions. Excellent edge line durability and surface finish. Can be used in both wet and dry conditions.

S40T

A very tough, medium-thick-coated CVD grade for roughing in toughness-demanding applications. Can be used in both wet and dry conditions.

GC1130

A hard PVD-coated Zertivo™ grade with thin coating, to be used as a complement to S30T for long time in cut. Can be used in both wet and dry conditions.

GC1010

A very hard and thin-coated PVD grade for finishing in very stable, wet or dry conditions.

Complementary grades

Highlights

Securing knowledge for future machining technology

Sandvik Coromant's role in academia is testimony to its dedicated position in the aerospace industry. At research institutions such as CCAM in Virginia, US and the AMRC in Sheffield, UK, Sandvik is delivering practical experience and knowledge-transfer for tomorrow's projects.

Struggling to find the right tool?

Let CoroPlus® ToolGuide help you get quick and accurate tool recommendations – on all your devices!

Join us. Stay updated.

Sign up for our newsletter today