CoroTurn® TR

Stable external and internal profiling

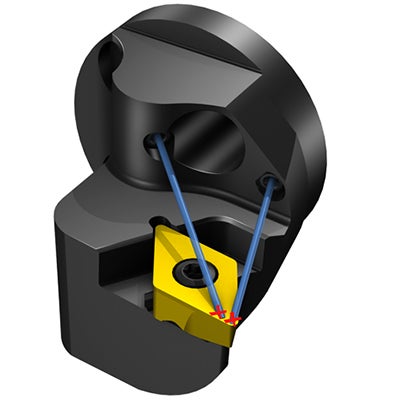

Stable insert clamping

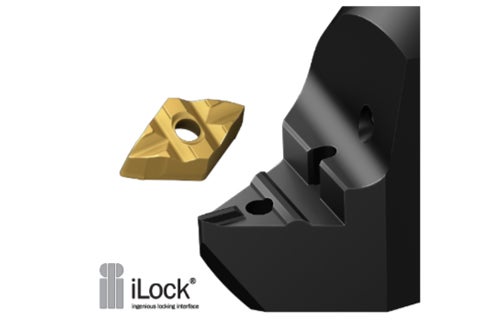

Tools with iLock® design have rails or serrations on the tool holder and corresponding slots on the insert for a tight locking. This prevents the cutting forces from affecting the tool position and ensures:

- High stability and tolerances

- Indexing repeatability

- Insert location accuracy within ±0.05 mm (±0.002 inch)

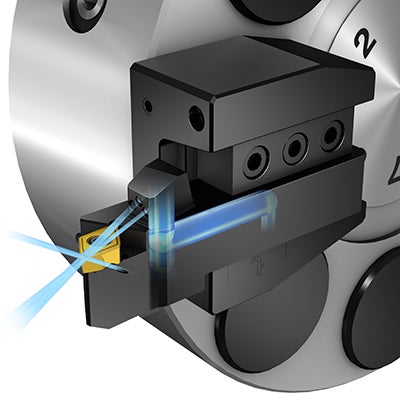

Chip control and process security

Pre-directed precision nozzles create laminar jets of over and under coolant with high velocity, directed at the right place of the insert edge. It is the precision and character of these jets that make the difference in terms of chip control and process security.

Handling efficiency

The coolant is easily connected thanks to support from a large assortment of plug and play adaptors including Coromant Capto®, VDI and machine specific adaptors for turning centres and QS™ stops (QS™ shanks) for sliding head machines.

Boost productivity

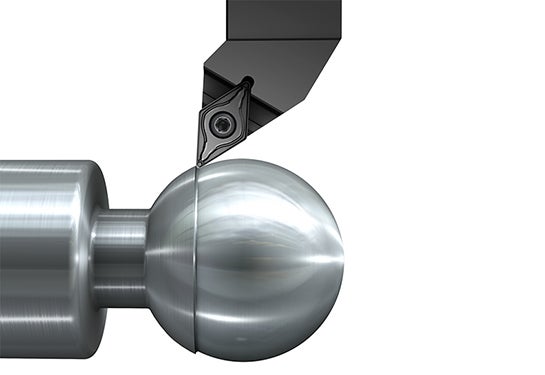

CoroTurn® TR inserts combined with PrimeTurning™ methodology revolutionizes the production of hardened components, delivering smarter and faster results. This innovative combination allows for higher cutting data, while keeping high surface repeatable quality.

Read more about CoroTurn® TR inserts used with PrimeTurning™ methodology in hard components here

Tool description

To achieve the highest profile quality, the key is to prevent cutting forces from causing micro-movements of the insert. The stable iLock® interface of CoroTurn® TR is developed to bridge this challenge, making it your first choice for external profiling.

Application

- First choice for external profiling

- Longitudinal turning

- Medium and finishing applications

- Turning centres, multi-task machining and large sliding head machines

Product range

Coromant Capto®

Sizes: C4, C5, C6, C7 and C8

Shank tools

Sizes: 1616 (10 inch), 2020 (12 inch), 2525 (16 inch), 3225 (1 1/4 inch)

QS™ shanks

Sizes: 2020 (12) and 2525 (16)

CoroTurn® SL heads

Sizes: 25, 32 and 40

Inserts

- D style (55º) inserts for medium and finishing applications and V style (35º) inserts for finishing.

Tailor Made

Sometimes that exact dimension you require might be missing. If so, turn to our Tailor Made service.

Experience the future of machining

CoroTurn® TR combined with PrimeTurning™ methodology is a game-changer set to transform hard part turning operations, bringing unparalleled productivity, security and surface quality.

Productivity

PrimeTurning™ methodology allows using higher feed rates.

Higher cutting data means increased component output and reduced cost-per-component.

Security

The iLock® from CoroTurn® TR interface ensures maximum insert stability in the tool holder and guarantees a precise and stable process.

Conventional solution vs. CoroTurn® TR combined with PrimeTurning™ methodology

Quality

The insert design allows for improved accessibility compared to conventional inserts and offers better surface quality while using high feed rates.

Highlights

Demo CoroTurn® Hard PrimeTurning

CoroTurn® TR Hard PrimeTurning™ delivers stability, speed, and extended tool life. From automotive components to any industry, it’s the ultimate machining solution. Unlock productivity with our secure locking interface and innovative methodology.

Increase output in steel turning

Steel turning often means continuously refining your machining processes. Small improvements in your turning strategy can make a big difference. Explore new technologies and methods that can provide you an edge over competition.

Turning the gear wheel

Achieving the right dimensions and tolerances in the soft stage is vital to succeed in the subsequent hard turning stage. Use CoroTurn® TR with iLock® design for stability and resistance towards insert movement. Combine with Coromant Capto® for unmatched stability all the way from the turret to the cutting edge.

Silent turning digitally connected

The Silent Tools™ Plus turning adaptor, featuring connectivity capability for digital machining, uses cutting heads with CoroTurn® TR inserts and includes a new Wedge Lock quick-change interface between the adaptor and cutting head. The fast and accurate cutting head changes will appeal to manufacturers in a variety of industries.

Struggling to find the right tool?

Let CoroPlus® ToolGuide help with quick and accurate tool recommendations, available on all your devices.

Join us. Stay updated.

Sign up for our newsletter today