CoroMill® MH20

High feed pocket milling

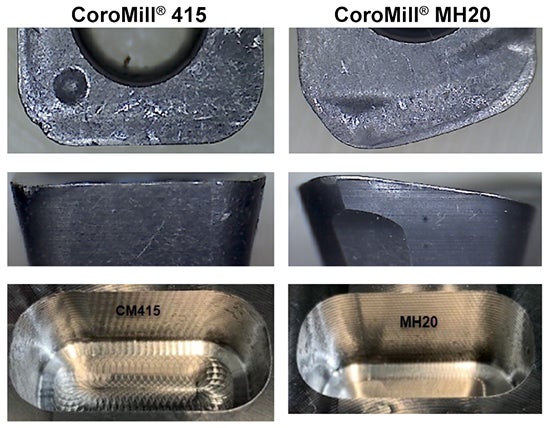

Performance test: ISO S

| Component: | Aerospace wing support |

| Material: | S4.3.Z.AN (Ti6Al4V) |

| Operation: | Pocketing |

| Machine: | Okuma M560V-Genos, CAT40 BIG-PLUS® |

+32% tool life

| CoroMill® 415 | CoroMill® MH20 | |

| Tool | 415-016A12-05H, zn: 3 | MH20-AR016O16-06L, zn: 2 |

| Insert | 415N-050212E-M30 S30T | M20-060320E-L30 S30T |

| Tool overhang, mm (inches) | 40 (1.575) | 40 (1.575) |

| vc, m/min (ft/min) | 69 (226) | 69 (226) |

| n, rpm | 1000 | 1000 |

| fz, mm/z (in/z) | 0.51 (0.020) | 0.51 (0.020) |

| vf, mm/min (in/min) | 1530 (60.2) | 1016 (40.0) |

| ap, mm (inches) | 0.8 (0.031) | 0.8 (0.031) |

| ae, mm (inches) | 16 (0.630) | 15.8 (0.622) |

| Tool life, min | 49 | 64.5 |

Result:

With the CoroMill® MH20, the customer improved the tool life by 32% and achieved much higher component surface quality. The insert corner of the CoroMill® MH20 showed better edge-line security and lower vibration tendency.

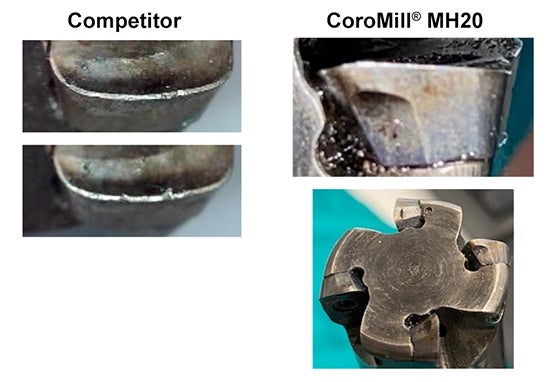

Performance test: ISO M

| Component: | Food processing machine component |

| Material: | M1.0.Z.AQ (AISI 304) |

| Operation: | Side and face milling |

| Machine: | DMG MORI NT4250, Coromant Capto® C6 |

Secure and reliable performance

| Competitor | Sandvik Coromant | |

| Tool | DCX: 25 mm (1 inch), zn: 4 | MH20-025A25-06H, zn: 4 |

| Insert | - | MH20-06 03 20E-L30 1040 |

| Tool overhang, mm (inches) | Chuck + 70 (2.76)=160 (6.30) | Chuck + 90 (3.54)=180 (7.09) |

| vc, m/min (ft/min) | 120 (394) | 120 (394) |

| n, rpm | 1530 | 1530 |

| fz, mm/z (in/z) | 0.85 (0.033) | 0.85 (0.033) |

| vf, mm/min (in/min) | 5200 (205) | 5200 (205) |

| ap, mm (inches) | 0.75 (0.030) | 0.75 (0.030) |

| ae, mm (inches) | 20 (0.787) | 20 (0.787) |

| Tool life, min | 3 components / 49.5 min | 3 components / 49.5 min |

Result:

After machining three components, the competitor insert clearly showed notch wear and micro chipping. The CoroMill® MH20 insert had less wear proving a reliable cutting edge with a secure and better edge-line quality.

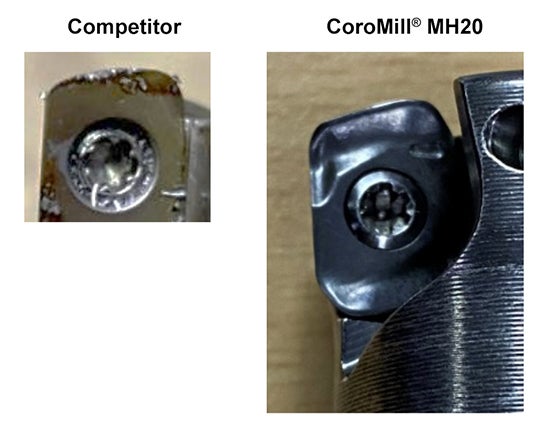

Performance test: ISO P

| Component: | Axis |

| Material: | P2.1.Z.AN (30CrMnSiNi2A), non-hardened |

| Operation: | Deep slotting and cut off |

| Machine: | Haitian HISION GLU16 VMC, BT50 |

+11% Productivity

| Competitor | Sandvik Coromant | |

| Tool | DCX: 25 mm (1 inch), zn: 3 | MH20-R025A25-08M, zn: 3 |

| Insert | - | MH20-08 04 25M-M50 4340 |

| Tool overhang, mm (inches) | Chuck + 122 (4.80) | Chuck + 110 (4.33) |

| vc, m/min (ft/min) | 142 (466) | 142 (466) |

| n, rpm | 1800 | 1800 |

| fz, mm (inches) | 0.426 (0.017) | 0.481 (0.019) |

| vf, mm/min (in/min) | 2300 (90.6) | 2600 (102) |

| ap, mm (inches) | 0.5 (0.020) | 0.5 (0.020) |

| ae, mm (inches) | 25 (0.984) | 25 (0.984) |

| Tool life, min | 1 component / 348 min | 1 component / 308 min |

Result:

The CoroMill® MH20 boosted productivity by 11% and showed less wear than the competitor, demonstrating secure and reliable performance.

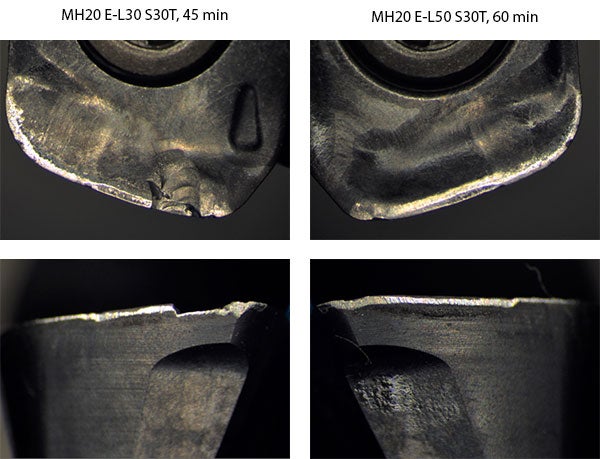

Performance test: Inconel

| Industry segment: | Aerospace |

| Component: | Demo component |

| Material: | S2.0.Z.AG (Inconel 718 aged HRC 44) |

| Operation: | Rough face milling |

| Machine: | DMG MORI, Coromant Capto®; C10, 5-axis VMC set-up |

| Coolant: | Internal (emulsion) |

+33% Tool life

Tool path generated in Siemens NX - Adaptive milling.

| Tool | Holder: CoroChuck® 930-HD Tool: MH20-R016A16-06L Insert: MH20-060320E-L50/L30 TS S30T |

| vc, m/min | 30 |

| fz, mm | 0.4 |

| hex, mm | 0.1 |

| vf, mm/min | 478 |

| ae, mm | 7 |

| ap, mm | 0.6 |

| Tool overhang, mm | 48 (3×DC) |

| Machining time, min | 60 (E-L50), 45 (E-L30) |

| MRR (Q), cm3/min | 1.92 |

Result:

Compared to E-L30, the E-L50 geometry shows higher edge line security in Inconel 718 machining and should be the first-choice recommendation.

Join us. Stay updated.

Sign up for our newsletter today