CoroMill® MH20

High feed pocket milling

Instructions

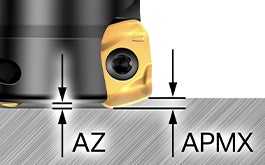

Maximum depth of cut (APMX)

The maximum depths of cut are:

IC06: 0.8 mm (0.031 inches)

IC08: 1.3 mm (0.051 inches)

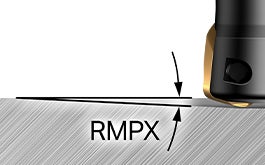

Ramping angle (RMPX)

The ramping angles are:

IC06: 3.6°–10.1°

IC08: 1.7°–10.7°

Programming radius (REEQ)

The programming radii are:

IC06: 2.0 mm (0.079 inches)

IC08: 2.5 mm (0.098 inches)

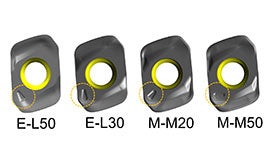

Marking of geometries

The inserts have a prominent marking to differentiate the geometries.

Application tips

Recommendations

Code keys

Cutter body

| M | H | 2 | 0 | - | (A) | R | 0 | 2 | 5 | A | 2 | 5 | - | 0 | 6 | M |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | ||||||

- Milling

- High feed

- Family = 2

- Version = 0

- Inch cutters

- R = Right hand

- DCX

- Coupling types

A/O = Cylindrical (metric/inch)

Q/R = Arbor (metric/inch)

EH = EH adaptor

- Coupling size

- Insert size

- Pitch: L/M/H

Insert

| M | H | 2 | 0 | - | 0 | 8 | 0 | 4 | 2 | 5 | M | - | M | 2 | 0 | 1 | 1 | 3 | 0 | |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | |||||||||||

- Milling

- High feed

- Family = 2

- Version = 0

- Insert size

- Thickness

- Programming radius

- Edge quality

E: Periphery ground

M: Direct pressed

- Geometry

- Grade

Geometries

|  |  |  |

| E-L30 | E-L50 | M-M20 | M-M50 |

| Periphery-ground geometry | Periphery-ground geometry | Direct-pressed geometry | Direct-pressed geometry |

| ISO S and M | ISO S and M | ISO P and H | ISO P |

|

|

|

|

Cutting data, feed recommendations

| ISO area | Grade | Insert size | Geometry | fz, start value (min-max) | |

| mm/z | inch/z | ||||

| ISO S (TiAl6V4) | S30T, S40T, GC2040 | IC06 | E-L30 | 0.3 (0.1–0.6) | .012 (.004–.024) |

| IC08 | E-L30 | 0.45 (0.1–0.6) | .018 (.004–.024) | ||

| IC06 | E-L50 | 0.35 (0.1–0.6) | .014 (.006-.024) | ||

| IC08 | E-L50 | 0.5 (0.1–0.6) | .020 (.006-.024) | ||

| ISO S (Inconel) | S30T, S40T, GC2040 | IC06 | E-L50 | 0.35 (0.1–0.6) | .014 (.006-.024) |

| IC08 | E-L50 | 0.5 (0.1–0.6) | .020 (.006-.024) | ||

| ISO M (316L) | GC1040, GC2040, S30T, S40T | IC06 | E-L30 | 0.3 (0.2–0.8) | .012 (.008–.031) |

| IC08 | E-L30 | 0.45 (0.2–0.8) | .018 (.008–.031) | ||

| IC06 | E-L50 | 0.35 (0.2–0.8) | .014 (.008-.032) | ||

| IC08 | E-L50 | 0.5 (0.2–0.8) | .020 (.008-.032) | ||

| ISO P | GC1130, GC4340 | IC06 | M-M20 | 0.6 (0.2–0.8) | .024 (.008–.031) |

| IC08 | M-M20 | 0.7 (0.2–1.0) | .028 (.008–.039) | ||

| IC06 | M-M50 | 0.8 (0.45–1.0) | .031 (.018–.039) | ||

| IC08 | M-M50 | 1.0 (0.45–1.3) | .039 (.018–.051) | ||

| ISO H | GC1010, GC1130 | IC06 | M-M20 | 0.45 (0.15–0.6) | .018 (.006–.024) |

| IC08 | M-M20 | 0.55 (0.1–0.8) | .022 (.039–.031) | ||

Cutting data, cutting speed recommendations

| ISO area | Grade | vc, (min-max) | |

| m/min | feet/min | ||

| ISO S (TiAl6V4) | S30T | 75–115 | 246–377 |

| S40T | 75–100 | 246–328 | |

| GC2040 | 31–40 | 102–131 | |

| ISO S (Inconel) | S30T | 40–60 | 131–197 |

| S40T | 40–60 | 131–197 | |

| GC2040 | 40–60 | 131–197 | |

| ISO M (316L) | GC1040 | 115–180 | 377–591 |

| GC2040 | 160–225 | 525–738 | |

| S30T | 155–250 | 509–820 | |

| S40T | 165–235 | 541–771 | |

| ISO P | GC1130 | 150–265 | 492–869 |

| GC4340 | 150–265 | 492–869 | |

| ISO H | GC1010 | 75–115 | 246–377 |

Helical ramping

| Metric cutters (DCX) | Inch cutters (DCX) | IC06 inserts | IC08 inserts | ||||||

| Max ap 0.8 mm (.031 inch) | Max ap 1.3 mm (.051 inch) | ||||||||

| Max ramping angle (RMPX) | Max Dm | Flat min Dm | Min Dm | Max ramping angle (RMPX) | Max Dm | Flat min Dm | Min Dm | ||

| 5/8 | 10.1° | 31.8 | 23.4 | 22.4 | |||||

| 16 | 9.5° | 32.0 | 23.6 | 22.6 | |||||

| 3/4 | 6.5° | 38.2 | 29.8 | 28.8 | 10.7° | 38.2 | 27.6 | 26.1 | |

| 20 | 5.8° | 40.0 | 31.6 | 30.6 | 9.6° | 40.0 | 29.4 | 27.9 | |

| 25 | 3.7° | 50.0 | 41.6 | 40.6 | 5.7° | 50.0 | 39.4 | 37.9 | |

| 1 | 3.6° | 50.8 | 42.4 | 41.4 | 5.5° | 50.8 | 40.2 | 38.7 | |

| 11⁄4 | 3.6° | 63.6 | 53.0 | 51.5 | |||||

| 32 | 3.6° | 64.0 | 53.4 | 51.9 | |||||

| 11⁄2 | 2.7° | 76.2 | 65.6 | 64.1 | |||||

| 40 | 2.5° | 80.0 | 69.4 | 67.9 | |||||

| 44 | 2.3° | 88.0 | 77.4 | 75.9 | |||||

| 50 | 1.7° | 100.0 | 89.4 | 87.9 | |||||

| 2 | 1.7° | 101.6 | 91.0 | 89.5 | |||||

| 52 | 1.6° | 104 | 93.4 | 91.9 | |||||

| 54 | 1.5° | 108 | 97.4 | 95.9 | |||||

| 63 | 1.1° | 126 | 115.4 | 113.9 | |||||

| 21⁄2 | 1.1° | 127 | 116.4 | 114.9 | |||||

| 66 | 1.0° | 132 | 121.4 | 119.9 | |||||

Plunge milling

Overhang L ≤ 3×D

Note! S must be ≤ 20 mm

| IC | Max ae, mm (inch) | Feed, mm/z (in/z) |

| 06 | 4 (0.157) | 0.10 (0.05–0.15) (0.004 (0.002–0.006)) |

| 08 | 5.5 (0.217) | 0.12 (0.05–0.15) (0.005 (0.002–0.006)) |

Overhang L ≥ 3×D

Note! S must be ≤ 20 mm

| IC | Max ae, mm (inch) | Feed, mm/z (in/z) |

| 06 | 4 (0.157) | 0.08 (0.05–0.15) (0.003 (0.002–0.006)) |

| 08 | 5.5 (0.217) | 0.1 (0.05–0.15) (0.004 (0.002–0.006)) |

Join us. Stay updated.

Sign up for our newsletter today