CoroTurn® XS

Internal machining of small, high-quality features

High precision and repeatability

These high-quality ground tools are designed for exact cutting-edge position, enabling high precision and repeatability in internal turning machining.

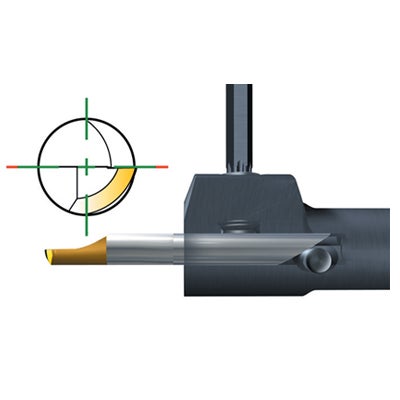

Locking precision

The solid carbide boring bar fits precisely into the adapter with a locating pin. Collet-clamped adapters ensure rigid clamping with increased stability.

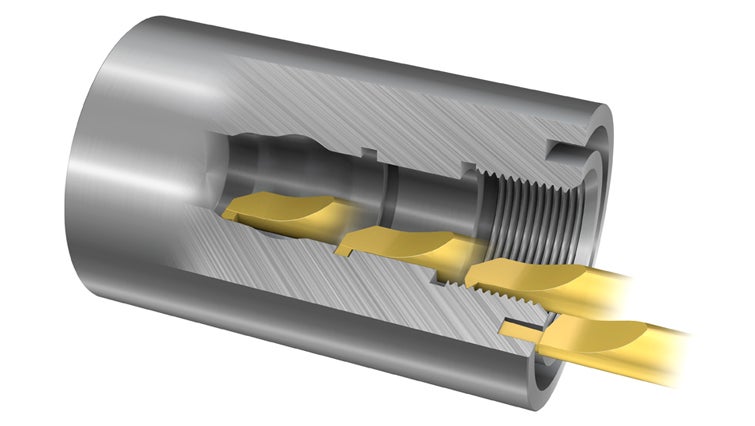

Internal coolant

All adapters for CoroTurn® XS are designed with internal coolant supply. Collet-clamped adapters have selectable coolant direction for better chip evacuation and safe machining.

Application area

- For internal finishing applications

- Hole diameter: 0.3–7.2 mm (0.012–0.283 inch)

- Internal turning, copying, back boring, profiling, grooving, pre-parting and threading

- Face grooving

Product range

Solid carbide tool

Sizes: 04, 05, 06, 07, 08 and 10

Grades

GC1125, GC1025, H10F, CB7014

Geometries

- Flat ground geometry with sharp edge line

- A-geometry with chip breaker for excellent chip control

Tool holding

- Collet-clamped adapters for sliding head machines

- Cylindrical shank with 2, 3 and 4 flats, single and double ended, for sliding head machines

- Square shank adapters for external tool post in sliding head machines

- Square shank adapters for general lathes

- Coromant Capto® for turning and rotating applications

- Coromant EH for rotating applications

Highlights

Join us. Stay updated.

Sign up for our newsletter today