CoroChuck® 930

High-precision hydraulic chuck For milling, drilling and reaming operations where precision and high pull-out security is required Available for the most common machine interfaces

Customer case, twin-screw manufacturing test

The customer experienced tool pull-out due to vibrations and tool wear.

| Component: | Twin-screw |

| Material: | Steel (42CrMo4) |

| Operation: | Milling |

| Machine: | DMG MORI NT6500/6000 |

| Chuck: | CoroChuck™ 930 HD25/C8 |

| Collet: | CLF 25/20 (393.CLF-252056) |

| End mill: | 2S342-2000-200-PA 1730 |

100%

pull-out security

| Cutting data | |

| n, rpm | 3,220 |

| vf mm/min (in/min) | 1,500 (590) |

| ap mm (inch) (differential) | 10 (0.394) (nominal) |

| ae mm (inch) (full slot) | 20 (0.787) |

| Result: | The mechanical locking interface solution generated a stable process and no pull-out. Productivity increased due to longer tool life. |

Customer performance test with CoroMill® Plura

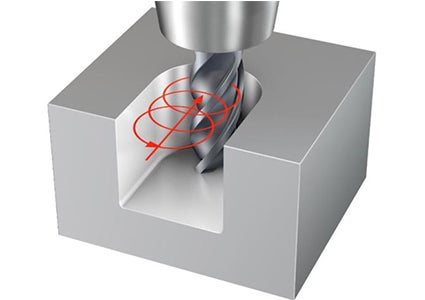

| Operation | Trochoidal milling |

| Workpiece material | Inconel 718 (CMC 20.22, MC S2.0.Z.AG) |

| Machine | Hermle C50 |

| Cutting data | CoroChuck™ 930 | Competitor |

| n rpm | 3,183 | 3,183 |

| vc m/min (ft/min) | 80 (260) | 80 (260) |

| ap mm (inch) | 18 (0.709) | 18 (0.709) |

| vf mm/min (in/min) | 763.92 (30.040) | 763.92 (30.040) |

| fz mm/z (in/z) | 0.06 (0.0024) | 0.06 (0.0024) |

| Results | ||

| Total machining time, min | 12 | 6 |

| Tool condition | Tool breakage | Tool breakage |

| CoroChuck™ 930 increased machining time by 100% due to better clamping conditions and damping abilities. |

Join us. Stay updated.

Sign up for our newsletter today