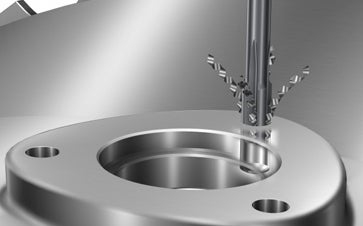

CoroReamer 835

CoroReamer 835 is optimized for specific materials. Internal coolant and extremely unequal spacing of the cutting edges are two features that promise really close hole tolerances and high-quality surface finish.

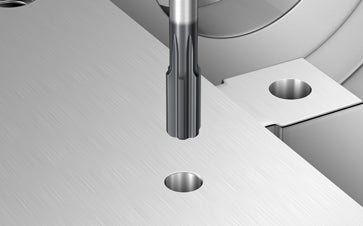

Correct diameter

Ensure that the pre-drilled hole has the correct diameter for stock removal allowance.

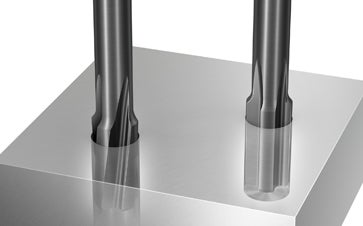

Rigid workpiece

Workpiece must be held rigid and the machine spindle should have no play.

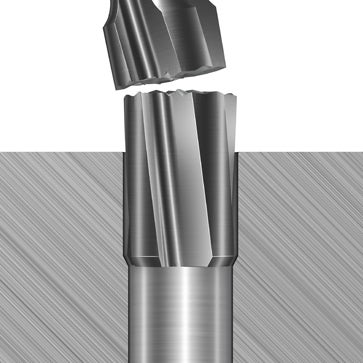

Short overhang

Keep the tool overhang from machine spindle to a minimum.

Lubrication

Use recommended lubricants.

Application tips

Initial considerations

To obtain the best results when using reamers it is essential to make them ‘work’. It is a common fault to prepare holes for reaming with too little stock left. If insufficient stock is left in the hole before reaming, then the reamer will rub, quickly show wear and will result in loss of diameter. It is equally important for performance not to leave too much stock in the hole.

Troubleshooting

Is your spindle or tool run-out too high? Do you have wrong cutting data, or perhaps wondering how to avoid a built-up edge during your reaming process? Check out our reaming troubleshooting guide.

Useful apps

Liity meihin. Pysy ajan tasalla.

Tilaa uutiskirje jo tänään