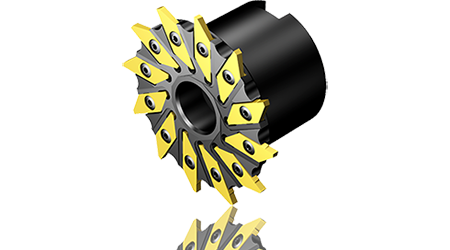

Gear milling with the CoroMill® 161 precision cutters, optimized for InvoMilling, is very flexible since the same tools are used for different gear profiles. This means that machining can start right away instead of having to wait for an engineered tool, ideal when machining small batches and when short lead times are a priority.

Flexibility

- Use the same cutters for many different gear profiles

- Small tool inventory

Short total manufacturing time

- Start machining right away – no need to wait for a gear profile specific tool

- Complete components in one set-up

Gear quality according to DIN 6

- The robust cutters are designed to adhere to the requirements of the InvoMilling process and give very accurate gears

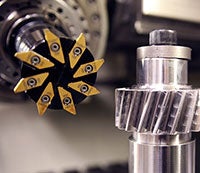

InvoMilling of helical gear with

CoroMill 161.

InvoMilling™ 2.0 은 InvoMilling™ 프로그래밍에 사용되는 소프트웨어입니다.

InvoMilling™ 성공 사례

스웨덴 리아토르프. SwePart Transmission은 범용 5축 기계에서 기어를 제조하기 위한 유연한 가공법인 InvoMilling을 사용해 기어 휠 프로토타입 제작의 리드타임을 크게 단축시켰습니다

.

InvoMilling을 사용한 헬리컬 기어 가공

Sandvik Coromant highlights - CoroMill® QD, CoroMill® Plura, InvoMilling™ 1.0

CoroMill® QD Solve common grooving challenges, such as chip evacuation and vibration... open_in_new

InvoMilling™ - flexible gear milling

Check out InvoMilling™, the innovative approach to milling spur and helical gears... open_in_new