CoroDrill 880

Indexable insert drills

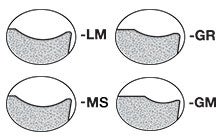

Select insert geometry

-LM - All-round chip breaker

- Low cutting forces

- First choice in low carbon steel

- Low to medium feed

-GR

- First choice in alloyed steel and ISO-K

- Medium to high feed

-MS

- First choice in ISO-M and ISO-N

- Sharp edge and low cutting forces.

-GM

- Low cutting forces

- Low to medium feed

Select grade

4334

- First choice in normal conditions in ISO-P and K

- Complementary choice in stable ISO-M applications

4324

- Wear resistant choice for ISO-P and K

4344

- Secure grade that works in all types of materials.

2044

- First choice in ISO-M

- Complementary in ISO-S

N124

- Diamond coated

- First choice in ISO-N

H13A

-Uncoated grade

Tool maintenance tips

Use a torque screw driver and a Molycote to ensure that the insert is securely seated. Change the insert screw regularly and ensure that the tip seat is clean and free from obstructions which could offset the insert.

Troubleshooting

For troubleshooting information check the guidelines on our knowledge portal.

Application guide

Achieving good hole quality

Achieving good hole quality may require some extra attention. Here you can find some useful tips to get you started.

Advanced operations

Advanced operations such as inclined or curved hole-entries, crossing holes and irregular surfaces require a bit of extra attention before machining. We have collected useful information to make advanced holes easy.

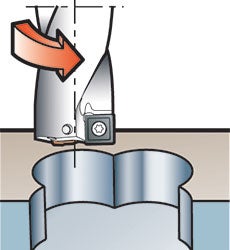

Quick pockets with plunge drilling

The fastest way to open up a cavity is by using the plunge drilling method. This method consists of drilling holes with a maximum step-over rate of 70%.

Apps for your convenience

Recommendations

Choose the right insert and grade combination

| First choice | Complementary choice | ||||

| Centre insert | Peripheral insert | Centre insert | Peripheral insert | ||

| Low-carbon steel | P | -LM 1044 | -LM 4334 | -LM 1044 | -LM 4324 -LM 4344 |

| Low-alloy steel | P | -GR 1044 | -GR 4334 | -GR 1044 | -GR 4324 -GR 4344 |

| Stainless steel | M | -LM 1144 | -MS 2044 | -LM 1044 | -LM 4344 |

| Cast Iron | K | -GR 1044 | -GR 4334 | -GR 1044 | -GR 4324 -GR 4344 |

| Non-ferrous metal | N | -LM N134 | -MS N124 | -LM H13A | -LM H13A |

| HRSA | S | -LM 1044 | -LM 4344 | -LM 1144 -LM H13A |

-MS 2044 -LM H13A |

| Hardened steels | H | -GM 1044 | -GM 4344 | -GR 1044 | -GR 4344 |

Highlights

High quality holes in one step

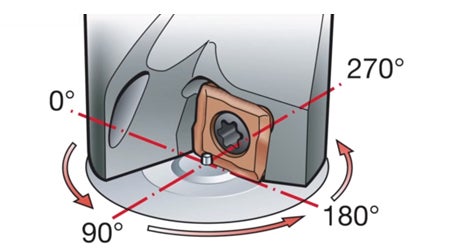

CoroDrill 880 is designed with a strong drill body with centre- and periphery-insert and features unique Step Technology™ for perfect cutting force balance.

How CoroDrill® 880 helped Valmet

Learn why Valmet welcomed the offer to test run a newly developed version of the CoroDrill® 880™, which features improvements that could potentially solve the problems the company was experiencing.

Minimizing tool run out in non-rotating applications

Watch the film to learn from our drilling expert how to secure alignment in lathe applications.

ลงทะเบียน ติดตามข่าวสาร

สมัครรับจดหมายข่าวของเราวันนี้