CoroMill® 331

多用途三面刃铣刀具

泰国客户案例

| 行业 | 机械工程 |

| 材料 | 高合金钢,CMC 3.11 (P3.1.Z.AN) |

| 工序 | 单侧铣 |

| 机床 | Mazak |

-73%

单个零件成本

+279%

生产率提高

| 刀具 | L331.52-160S40FM | N331.32-200Q40FM12.00 |

| 刀片 | N331.1A-08 45 08H-PL 4240 | N331.1A-08 45 08E-M30 1130 |

| DC | 160 (6.3) | 160 (6.3) |

| Zn | 12 | 12 |

| n,rpm | 450 | 350 |

| vc,m/min (英尺/分钟) | 226 (741) | 176 (577) |

| hex,mm (英寸) | 0.017 (0.0007) | 0.078 (0.0031) |

| fz,mm (英寸) | 0.02 (0.001) | 0.09 (0.004) |

| vf,mm/min (英寸/分钟) | 108 (4) | 375 (15) |

| ap,mm (英寸) | 6 (0.236) | 6 (0.236) |

| ae,mm (英寸) | 40 (1.575) | 40 (1.575) |

| 换刀标准 | 刀片崩刃 | 刀片崩刃 |

| 切削时间 (分钟) | 68.5 | 18 |

| 刀具寿命 (零件数量) | 14 | 37.5 |

结果

全新E-M30槽型将生产率提高了279%,并且大幅降低了单个零件成本。

美国客户案例

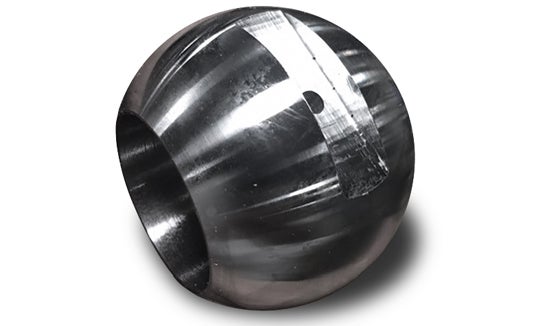

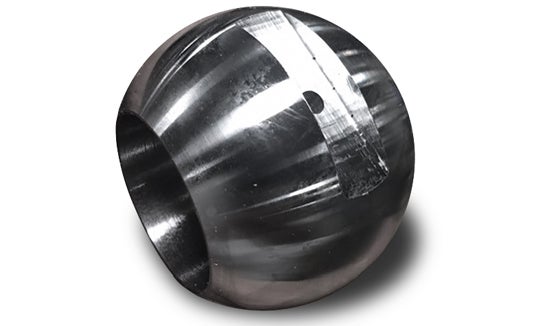

| 零件 | 流量控制球阀 (石油和天然气) |

| 材料 | M1.0.Z.AQ (316 SS) |

| 工序 | 切槽 |

| 机床 | 专用机床 |

| 刀具 | N331.32-152T38EM0.394 | N331.32-152T38EM0.394 |

| 刀片 | N331.1A-08 45 08H-PL S30T | N331.1A-08 45 08E-L50 S30T |

| DC | 152 | 152 |

| zn (zeff) | 12 (6) | 12 (6) |

| n,rpm | 1109 | 1109 |

| vc,m/min (英尺/分钟) | 529 (1736) | 529 (1736) |

| hex,mm (英寸) | 0.036 (0.001) | 0.036 (0.001) |

| fz,mm (英寸) | 0.1 (0.004) | 0.1 (0.004) |

| vf,mm/min (英寸/分钟) | 658 (25.9) | 658 (25.9) |

| ap,mm (英寸) | 11.5 (0.453) | 11.5 (0.453) |

| ae,mm (英寸) | 5.5 (0.217) | 5.5 (0.217) |

| 单个零件切削时间,秒 | 2.5 | 2.5 |

| 刀具寿命,零件数量 | 210 | 260 |

结果

通过将H-PL槽型替换为全新L-50槽型,刀具寿命延长了24%,磨损形式也明显更加可靠和可预测。

美国客户案例

| 零件 | 航空航天螺母管节 |

| 材料 | S2.0.Z.AN (Inconel 625) |

| 工序 | 排铣 |

| 机床 | 卧式心轴安装式手动铣床 |

67%

刀具寿命延长

| 刀具 | R331.52-127T38EM L331.52-127T38EM | R331.52-127T38EM L331.52-127T38EM |

| 刀片 | N331.1A-08 45 08H-PL S30T | N331.1A-08 45 08 L50 S30T |

| DC | 127 | 127 |

| zn (zeff) | 10 (10) | 10 (10) |

| n,rpm | 142 | 142 |

| vc,m/min (英尺/分钟) | 56.7 (186) | 56.7 (186) |

| hex,mm (英寸) | 0.051 (0.002) | 0.051 (0.002) |

| fz,mm (英寸) | 0.051 (0.002) | 0.051 (0.002) |

| vf,mm/min (英寸/分钟) | 72.95 (2.87) | 72.95 (2.87) |

| ap,mm (英寸) | 1.27 (0.050) | 1.27 (0.050) |

| ae,mm (英寸) | 16.26 (0.640) | 16.26 (0.640) |

| 单个零件切削时间,秒 | 25.0×3次转位切削 | 25.0×3次转位切削 |

| 刀具寿命,零件数量 | 120 | 200 |

结果

全新L50刀片具有出色的刀具寿命以及可预测、可靠的刀具磨损。其他令人赞赏的改进包括更少的振动和更好的表面质量。

印度客户案例

| 零件 | 机车主连杆 |

| 材料 | CMC 2.2钢 |

| 工序 | 通过插补铣进行油槽粗加工 |

| 机床 | Mazak (马扎克) Nexus 5000-II |

| 刀具 | R331.35-063A25EM (Z6) | R331.35-063A25EM (Z6) |

| 刀片 | N331.1A-08 45 08H-NL 1025 | N331.1A-08 45 08E-M30 1130 |

| DC | 63 | 63 |

| zn (zeff) | 6 (3) | 6 (3) |

| n,rpm | 960 | 960 |

| vc,m/min (英尺/分钟) | 190 (623) | 190 (623) |

| hex,mm (英寸) | 0.015 (0.0006) | 0.015 (0.0006) |

| fz,mm (英寸) | 0.03 (0.001) | 0.03 (0.001) |

| vf,mm/min (英寸/分钟) | 58 (2.28) | 58 (2.28) |

| ap,mm (英寸) | 10 (0.394) | 10 (0.394) |

| ae,mm (英寸) | 3 (0.118) | 3 (0.118) |

| 磨损 | 崩刃 | 后刀面磨损和热裂纹 |

| 刀具寿命,零件数量 | 8 | 16 |

结果

更长的刀具寿命,更加可靠、可预测的刀具磨损。切削声音也大幅改进。

Customer case, France

| Component | Housing for tractor |

| Material | Cast iron FGL 300 (K2.2.C.UT) |

| Operation | Side and face milling with interpolation |

| Machine | HMC (HSK100) |

| Existing insert (M-KM 1020) | New insert (M30 1020) | |

|---|---|---|

| Tool | 203 24 0242 R 0114 | 203 24 0242 R 0114 |

| Insert | N331.1A-08 45 08M-KM 1020 | N331.1A-08 45 08 M30 1020 |

| DC | 50 | 50 |

| zn, (zeff) | 6 (6, big overlap) | 6 (6, big overlap) |

| n, rpm | 1561 | 1561 |

| vc m/min (ft/min) | 245 (804) | 245 (804) |

| hex mm (inch) | 0.21 (0.008) | 0.21 (0.008) |

| fz mm (inch) | 0.21 (0.008) | 0.21 (0.008) |

| vf, mm/min (in/min) | 1965 (77.4) | 1965 (77.4) |

| ap mm (inch) | 10 (0.394) | 10 (0.394) |

| ae mm (inch) | 14 (0.551) | 14 (0.551) |

| Time in cut / component, min | 0.84 | 0.84 |

| Tool life, components | 37 | 37 |

Result

The new M30 insert provided more controlled and less tool wear for the same number of components and less spindle load.

Half side and face milling

| Component | General engineering |

| Material | CMC 01.3 (P1.3.Z.AN) |

| Operation | Half side and face milling |

| Machine | Heller MCH350 |

+569%

Productivity

Productivity

-394 HRS

Machine time

Machine time

| | Competitor | CoroMill® 331 |

|---|---|---|

| Tool | R331.32-125Q32 KM 15 | |

| Insert | N331.1A-115008M-PM4230 | |

| DC mm (inch) | 125 (5.0) | 125 (5.0) |

| zn | 10 (zeff10) | 8 (zeff8) |

| n, rpm | 530 | 790 |

| vc m/min (ft/min) | 208 (682) | 310 (1017) |

| hex mm (inch) | 0.05 (0.0020) | 0.12 (0.0047) |

| fz mm/z (in/z) | 0.08 (0.0031) | 0.18 (0.0071) |

| vf, mm/min (in/min) | 424 (16.693) | 1138 (44.803) |

| ap mm (inch) | 5 (0.197) | 8 (0.315) |

| ae mm (inch) | 12 (0.472) | 15 (0.591) |

| Cycle time, min | 33.96 | 5.01 |

| Results | ||

| Tool life, components | 8 | 12 |

| Tool life, m (feet) | 115.12 (377.69) | 68.42 (224.47) |

| Tool life, min | 271.68 | 60.12 |

Customer case, Russia

| Industry: | Automotive |

| Component: | Connecting rod cap |

| Material: | Cast iron (K2.1.C.UT) |

| Operation: | Mill full slot |

| Machine: | Special arbor-mounted automatic milling machine |

| Coolant: | Emulsion, 7% |

33%

Increased tool life

Increased tool life

| Existing insert (M-KM 3040) | New insert (M30 1020) | |

| Insert | N331.1A-08 45 08M-KM3040 | N331.1A-08 45 08 M30 1020 |

| DC | 125 | 125 |

| zn (zeff) | 16 (8) | 16 (8) |

| Tool overhang | Arbor-mounted | Arbor-mounted |

| n, rpm | 207 | 207 |

| vc, m/min (ft/min) | 81.5 (267) | 81.5 (267) |

| hex mm (inch) | 0.05 (0.002) | 0.05 (0.002) |

| fz mm (inch) | 0.12 (0.005) | 0.12 (0.005) |

| vf, mm/min (in/min) | 200 (7.87) | 200 (7.87) |

| ap mm (inch) | 6.0 (0.236) | 6.0 (0.236) |

| ae mm (inch) | 15 (0.591) | 15 (0.591) |

| Time in cut/component (sec) | 20.0 | 20.0 |

| Spindle load | NA | NA |

| Tool life, components | 3000 | 4000 |

Result

The new insert provided an improved, safe machining process with no cracks, less sound and with no vibration.

Oil groove finishing

| Industry | Automotive engine |

| Component: | Connecting rod |

| Material: | CrMo steel forging |

| Operation: | Oil groove finishing |

| Machine: | Vertical M/C |

| Coolant: | Emulsion, 8% |

| Existing insert (M-PM 4320) | New insert (M30 4230) | |

| Tool | N331.32-080S27EM(Z6) | N331.32-080S27EM(Z6) |

| Insert | N331.1A-084508M-PM 4230 | UVM3667-PMD-009 M30 4230 |

| DC | 80 (3.15) | 80 (3.15) |

| zn | 6 | 6 |

| n, rpm | 600 | 600 |

| vc, m/min (ft/min) | 150 (492) | 150 (492) |

| fz mm (inch) | 0.056 (0.002) | 0.056 (0.002) |

| vf, mm/min (in/min) | 100 (3.94) | 100 (3.94) |

| ap mm (inch) | 12 (0.472) | 12 (0.472) |

| ae mm (inch) | 2 pass 3+2.5 | 2 pass 3+2.5 |

| Average flank wear, mm (inch) | Less than 0.1 mm (0.004), even | Less than 0.1 mm (0.004), even |

| Tool life (components) | 15 components | 15 components |

Result

Existing M-PM shows slightly vibration-affected surface quality within specification. M30 however, shows good surface quality without vibration. M30 also proved much more light-cutting than the existing M-PM geometry.

Full slotting with interpolation

| Component | Valve body (oil and gas) |

| Material | CMC 02.2 (P2.5.Z.HT) |

| Operation | Full slotting with interpolation |

| Machine | HYUNDAI03 |

+195%

Productivity

Productivity

-500 HRS

Machine time

Machine time

| | Competitor | CoroMill® 331 |

|---|---|---|

| Tool | TMR331.35-520743 | |

| Insert | L331.1A-08 45 30H-WL 1030 | |

| DC mm (inch) | 80 (3.15) | 86 (3.4) |

| zeff | 4 | 4 |

| n, rpm | 500 | 650 |

| vc m/min (ft/min) | 175 (574) | 175 (574) |

| fz mm/z (in/z) | 0.1 (0.0039) | 0.2 (0.0079) |

| vf, mm/min (in/min) | 200 (7.874) | 520 (20.472) |

| ap mm (inch) | 1 (0.039) | 10 (0.394) |

| ae mm (inch) | 80 (3.150) | 60 (2.362) |

| Cycle time, min | 30 | 10 |

| Results | ||

| Tool life, components | 4 | 4 |

| Tool life, m (feet) | 12 (39.37) | 20.8 (68.24) |

| Tool life, min | 120 | 40 |

Boss milling

| Component | Turbine support case |

| Material | CMC 20.22 (S2.0.Z.AG) |

| Operation | Boss milling (interpolation) |

| Machine | Chiron |

+166%

Productivity

Productivity

-382 HRS

Machine time

Machine time

| Competitor | CoroMill®331 | |

|---|---|---|

| Tool | R331.35-050A20CM060 | |

| Insert | N331.1A-043505H-PL S30T | |

| DC mm (inch) | 50 (2.0) | 50 (2.0) |

| zn | 4 (zeff2) | 6 (zeff3) |

| n, rpm | 255 | 255 |

| vc m/min (ft/min) | 40 (131) | 40 (131) |

| hex mm (inch) | 0.01 (0.0004) | 0.02 (0.0008) |

| fz mm/z (in/z) | 0.01 (0.0004) | 0.02 (0.0008) |

| vf, mm/min (in/min) | 7 (0.276) | 18 (0.709) |

| ap mm (inch) | 1 (0.039) | 1 (0.039) |

| ae mm (inch) | 6 (0.236) | 6 (0.236) |

| Cycle time, min | 346 | 118 |

| Results | ||

| Tool life, components | 0.09 | 0.25 |

| Tool life, m (feet) | 0.04 (0.131) | 0.11 (0.361) |

| Tool life, min | 29.5 | 29.41 |

Deep grooving

| Component | Aircraft frame |

| Material | CMC 23.22 (S4.3.Z.AG) |

| Operation | Deep grooving |

| Machine | Gidding & Lewis |

+826%

Productivity

Productivity

-76 HRS

Machine time

Machine time

| Competitor | CoroMill® 331 | |

|---|---|---|

| Tool | N331.32-203T51FMB | |

| Insert | R331.1A-084530H-WL 1030 | |

| DC mm (inch) | 203 (8.0) | 203 (8.0) |

| zn | 18 (zeff6) | 16 (zeff8) |

| n, rpm | 73 | 72 |

| vc m/min (ft/min) | 46 (151) | 46 (151) |

| fz mm/z (in/z) | 0.051 (0.002) | 0.127 (0.005) |

| vf, mm/min (in/min) | 22.25 (0.876) | 72.77 (2.865) |

| ap mm (inch) | 7.62 (0.300) | 13.46 (0.530) |

| ae mm (inch) | 12.7 (0.500) | 12.7 (0.500) |

| Cycle time, min | 37.5 | 6.5 |

| Results | ||

| Tool life, components | 0.5 | 8 |

| Tool life, m (feet) | 0.42 (1.37) | 3.78 (12.41) |

| Tool life, min | 18.75 | 52 |

加入我们,获取最新信息!

现在订阅我们的新闻快讯