Quick change tooling solutions

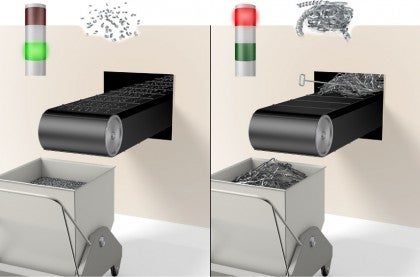

When people talk about productivity, the focus can often be on metal cutting efficiency. However, machine utilization or the time during which the machine's green light is on is equally or even more important.

With the quick change tooling solution, you can really increase your machine utilization by reducing measuring, set-up and tool change times.

Productivity factors

Productivity is the number of parts produced per shift or week. Understanding where the biggest improvements can be made is vital before considering which solutions to implement. There are two important factors to take into account:

- Metal-cutting efficiency – this can be measured in terms of metal removal rate (cm3/min (in3/min)) for any operation

- Machine utilization – this can be measured in the percentage of time the machine's green light is on (the ability to maintain continuous production for a long period)

Machine utilization is very much linked to the machine configuration and options. This needs to be considered prior to new machine investment to make sure the best technologies are implemented.

Typical time killers in factories reducing machine utilization are:

- Batch set-up

- Measuring the component in the machine

- Tool setting in the machine

- Coolant pipe setting

- Changing worn tools

- Chip removal around tools or blocked conveyors

- Component changeover

How tools are loaded and measured has a huge impact on the machine utilization—the best comparison is auto racing and minimizing the time the car is at the pit stop, which is why minimizing any machine stoppages is so important.

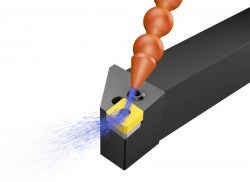

Through coolant delivery ensures that the full capabilities of the machine are harnessed with optimized cutting units to reduce setting and deliver the coolant with maximum impact to provide chip control.

Quick change tooling benefits

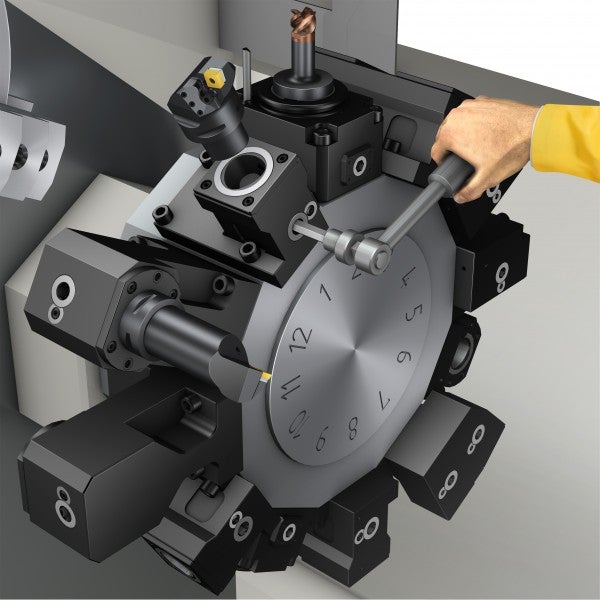

CNC lathes and sliding head machines offer fast tool indexing but typically lower utilization than machining centers due to the tool change and set-up time. Manual quick change is utilized where there is no automatic tool change (ATC) in the machine, ensuring the machine's green light is on for longer. There are many benefits of using quick change.

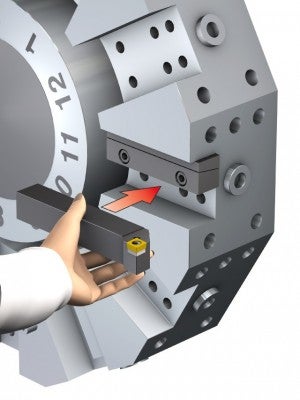

Reduced batch changeover time using tool kits

Changing from one type of tool to another is dramatically reduced.

- Turning tool holders from 5-10 min down to 30 seconds

- Boring bars take a little bit more time than shank tools because of center height setting and coolant plumbing

- There are even more advantages of quick change tooling in combination with long boring bars. Boring bars up to 10 x D can be changed with 2 μm (78.7 μinch) accuracy in less than 1 minute

- Driven tools from 5-20 min down to 30 seconds. Normal driven tools holders are ER or face milling. ER is limited to end mills with maximum diameter 25 mm (1 inch), which means two separate driven holders. With Coromant Capto®, the same unit covers all applications

Increased number of tool positions

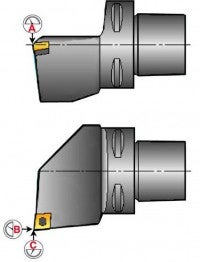

The increased number of tool positions with double tool holders allows the block to be used for both internal and internal operations.

Turning centers with driven tool holders often have limited space. Using double clamping units allows either sister tooling or an increased variety of tools, thereby reducing tool change requirement for a wider range of components. Double clamping units can be used when the machine has Y-axis, half turret or sub-spindle.

Reduce worn tool indexing time

Driven tool holders: Each time a solid carbide tool is changed, the tool offset needs to be re-calibrated. With indexable mills/drills, multiple inserts need to be changed. Using sister tools and changing the cutter outside the machine are much quicker.

Static tool holders: For single inserts with good accessibility it can be as quick to change directly in the machine. However, being able to remove the tool ensures improved maintenance of the tool, correct mounting and no unexpected stops due to the need for spare part purchases.

Eliminate coolant pipe setting

This varies from application to application but where operators are setting the coolant pipe direction, it normally takes two to three attempts to get it right – red light on! Poor chip control then often knocks the pipe, which means that setting is quite a regular occurrence.

Quicker production start-up

By eliminating either the "first test component" or "measuring cuts", the production rate is increased and scrap reduced. Calculated throughout the year, if quick change was used, the number of additional components produced and reduced scrap rate is significant.

- First test component for higher volume production: The first component following each tool change is often scrapped and the tool change time needs to be considered as follows; changing the tool (keeping the old offset), cutting a complete part, measuring the finished component and adjusting offset

- Measuring cuts for low/medium volume production: Taking a measuring cut with backed off offset ensures that the component is not scrapped but can take longer. Tool change time needs to be considered, including time for changing the tool, backing off offset, cutting, measuring and adjusting offset

Ergonomic and easy-to-use for the operator

Quick change has many benefits for the operator, for example, changing tools outside the machine reduces accidents, errors and searching for dropped parts. It is also easy to standardize in all machine types.

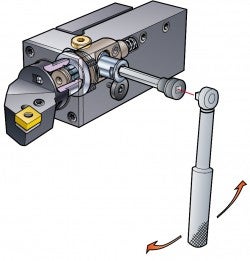

Quick change in sliding head machines

Due to the compact nature of sliding head machines, space for tool changing is limited. Often, shank tools need to be removed to index the insert which increases the set-up time compared to conventional turning centers.

Quick change, such as QS™ holding system, maximizes active production time in sliding head machines compared to conventional shanks. The tool can be removed from the machine for insert indexing, and with the fast and accurate return, you can start running immediately, without the need for setting/measuring.

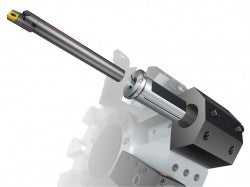

Quick setting of boring bars

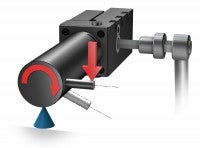

Setting of boring bars in the turret takes longer than a shank tool due to length/center height positioning as well as plumbing through coolant into the back of the tool.

Sleeves such as EasyFix offer a fast and simple way of achieving the correct center height when mounting cylindrical boring bars in the machine. A spring plunger solution mounted in the sleeve clicks easily into a groove in the bar to guarantee the correct center height, ensuring consistently high part quality.

The sleeve is available in a metallic sealed version for high-pressure coolant as well as the original with a slot filled with a silicon sealer for low coolant pressures.

Quick change with Coromant Capto®

Coromant Capto® is a modular quick change tooling concept which ensures that both machine utilization and metal cutting efficiency are maximized. Below are some of the key benefits of Coromant Capto®.

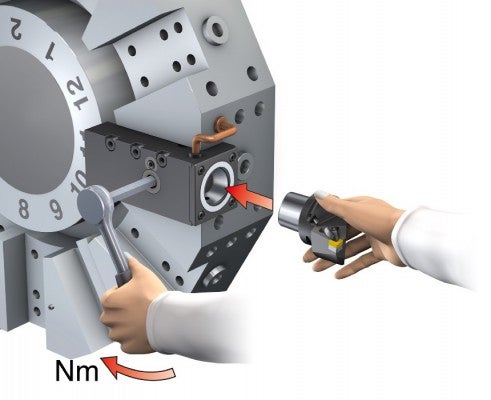

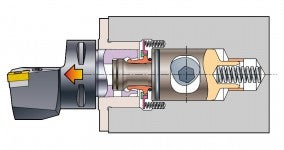

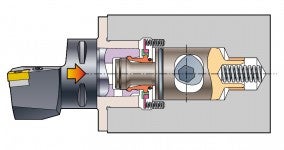

Segment clamping

The camshaft activated draw bar is used for both locking the coupling, with segment clamping, and for pushing out the cutting head. Only one turn is needed to lock and unlock the manual clamping unit. The camshaft has a self-locking angle and will not open during machining.

Repeatability

The high precision of the coupling and its self-centering design ensures repeatable accuracy of less than ±2 microns in the x-, y- and z-axis for the same cutting unit in the same female receiver.

This allows pre-setting outside the machine for high batch production or tool kits for batch change over. Both eliminate measuring cuts, allowing faster start-up and reduced scrap rates.

Increased stability

Stability is measured in terms of bending stiffness and torque transmission. The key features offering superior stability are as follows:

- Face and taper contact: Resisting bending moments and providing positional accuracy

- Polygon coupling: The large contact area transmits torque without any loose parts such as pins or keys. The torque load is spread symmetrically without peaks and irrespective of direction, with the polygon shape self-centering for accurate tip-seat center height

- High clamping force: The segment clamping generates high clamping forces, ensuring a press fit and a two-face contact resisting the bending moment generated during cutting

Read more about torque transmission and bending stiffness

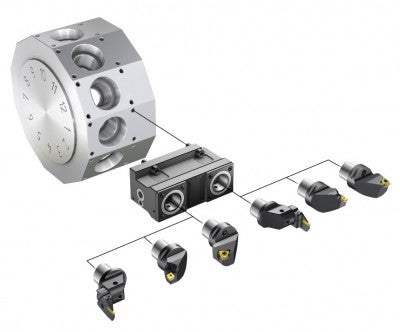

Clamping unit range

C3 through to C10 are all used for quick change on CNC lathes. The size is dependent upon the machine size and cutting parameters.

Vertical lathe RAM interfaces vary, and the manual clamping unit block with Coromant Capto® clamping units is supplied directly by the machine tool builder with the machine, or is ordered separately as a special block.

VDI-DIN 69880

Shank

CBI (Bolt on)

CDI

Dovetail VDI-DIN 69881

VTL – machine-specific

Coromant Capto® clamping units for bolt-on interfaces (CBI)

Machine adapted clamping units (MACU) are available as standard products for many machine tool builders' own turret interface designs.

Automatic tool change in turning centers

For larger vertical turning centers, an automatic tool change option with disc magazine is available that allows long boring bars to be stored. The more tooling positions available, the more flexibility and the possibilities for unmanned production increase.

For turning centers equipped with an ATC-MACU turret, automatic tool change is available for static and driven tool holders. Due to frequent manual tool changes, machine utilization in turning centers is typically low. Automatic tool change solves this problem, because it enables unmanned production, which in turn increases output and stabilizes the production process.

Automatic tool change in turning centers is a game-changing solution that enables unmanned production and maximizes output.

Coromant Capto® disc interface (CDI)

CDI was developed as a turret interface which can be standardized regardless of the machine type as a replacement for VDI. The CDI turret option is available for many machine tool builders.

Non-standard clamping units – Clamping unit sets

Clamping unit sets are used to tailor clamping units to specific requirements. These are used commonly for tool blocks for vertical lathes, double units or retrofitting quick change onto existing turrets.

The clamping set sleeves are available in different forms depending upon the application.

General

Square – double units

Offset – boring bar applications

Styles of machine specific clamping units

External – OD turning

Cx-TRE-xxxxA

Single external

Cx-TRE-xxxxA-DT

Double for sub- spindle

Cx-TRE-xxxxA-YT

Y-axis

Cx-TRE-xxxxA-TT

Half turret

APB-TNE-xxxxA-25

Parting blade adapter

Internal – ID turning/drilling

Cx-TRI-xxxxA

Single internal

Cx-TRI-xxxxA-SS

Sub-spindle

Cx-TRI-xxxxA-DT

Double for sub-spindle

Cx-TRI-xxxxA-YT

Y-axis

Cx-TRI-xxxxA-TT

Half turret

Driven

Cx-DTE-xxxxA-E/I

External

Cx-DTI-xxxxA-E/I

Internal

Modular solutions

Modular tooling systems provide the ability to build an optimized and tailored assembly... chevron_right

Tooling considerations

There is no quick answer to how to best configure your tools in the machine. By choosing... chevron_right

Crankshaft solutions

Sandvik Coromant has an extensive and complete offering for crankshaft machining,... chevron_right

Shaft

Made from high-alloy steel or Inconel, the major challenges when machining shafts... chevron_right